Zogulitsa

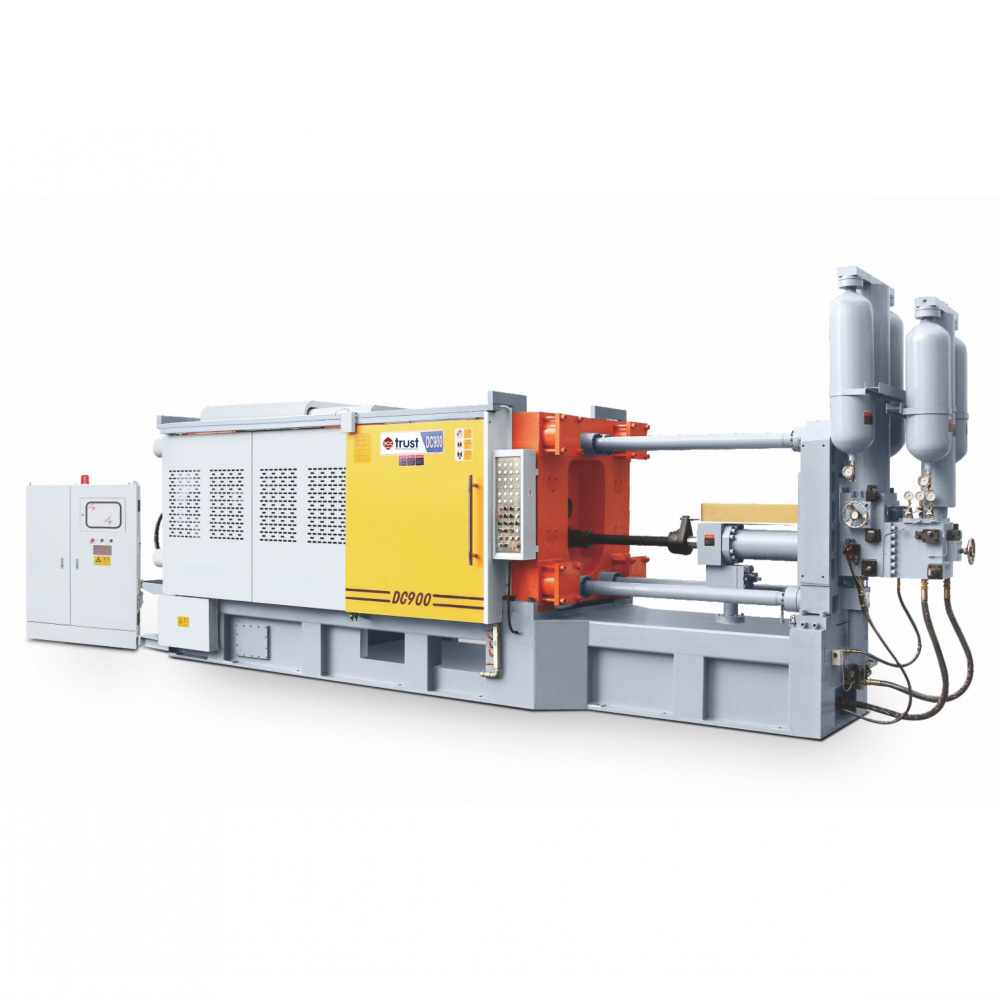

2500Ton Precision High Pressure Aluminium Alloy Cold Chamber Die Casting Machine

Mawonekedwe

1. Zinthu zopangidwa ndi nkhungu zopangidwa ndi nodular cast iron ndi alloy material yapadera. ndi ductility wabwino ndipo akhoza bwino kuyamwa mphamvu ya jekeseni; High pamwamba kuuma, bwino kuchepetsa kufa extrusion ndi zotsatira zizindikiro. Mapangidwewo amatengera mapangidwe okhuthala kuti awonetsetse kuti mawonekedwewo asakhale osavuta kugwa ndi kusweka pakagwiritsidwa ntchito nthawi yayitali.

2. The zosunthika nkhungu platen utenga nthiti mbale kapangidwe kamangidwe, amene osati kumawonjezera mphamvu ya mbale pakati pa dongosolo, komanso amathetsa mndandanda wa mavuto alipo inaimitsidwa thimble dongosolo ambiri ntchito makampani.

3. Malumikizidwe onse osuntha a makinawo adzaperekedwa ndi chitsamba chachitsulo cha alloy, ndipo ndi madzi a nayitrogeni ozizira amalipiritsa njira, kupanikizika kwa mgwirizano kudzakhala yunifolomu, kuti apititse patsogolo moyo wautumiki wa makinawo.

4. Malinga ndi kapangidwe ka makina otumizidwa kunja, makina opangira ma frequency amatengera ulusi wa tayi-bar, womwe umapangitsa kuuma ndi kuvala kukana kwa ulusi, ndikuthetsa mavuto omwe amabwera chifukwa cha kusintha kwa nkhungu ndi kupsinjika kwa ulusi mumakampani. .

5. Makina opangira makina amatengera mawonekedwe achitsulo opangidwa ndi I ndikuwonjezera chitsulo chothandizira. Kuphatikizidwa ndi njira yochizira kutentha, imakhala ndi kukhazikika bwino komanso sikophweka kufooketsa, kusunga bwino kugwiritsa ntchito makina kwa nthawi yayitali.

6. Zida zapadera za alloy ndi njira yochizira kutentha zimatengera tayi-bar, ndipo njira yowongoka ndi yopingasa ya njira ziwiri yotulutsa nkhawa imawonjezeredwa kuti zitsimikizire kukhazikika kwamphamvu kwa makina onse ndikutalikitsa moyo wautumiki wa tayi- bala.

7. Dongosolo la jekeseni lapamwamba kwambiri, lokhala ndi jekeseni yogwira ntchito komanso ndondomeko yowonongeka, yokhala ndi mphamvu yosungiramo mphamvu yosungiramo mphamvu, imakonzekeretsa kayendedwe ka mafuta a jekeseni, imachepetsa kutayika panthawi yopititsa mphamvu, kuthamanga kwa jekeseni kumafika 60g, ndipo imathandizira kwambiri kukhazikika komanso kubwereza kwa magawo ofunikira. Kuphatikiza apo, jekeseniyo imakhala ndi ntchito yosungiramo mphamvu yokhayokha, kuwerengera basi ndi ntchito yofananira ya kukakamiza kosungirako mphamvu, ntchito ya alarm ya kulephera kwa alamu, ntchito ya nitrogen leakage alarm, ntchito yotsitsa yokha, ndi zina zambiri.

8. Njira yosinthira valve ya cartridge, yodzipangira yokha ya cartridge valve yosinthira, idathetsa zovuta zaukadaulo zazovuta zosintha mumakampani.

9. Maonekedwe opangidwa motsogozedwa ndi gulu lotsogola kwambiri padziko lonse lapansi lopanga mafakitale apereka mapangidwe atsopano kwa makasitomala pafupifupi 2000 padziko lonse lapansi, okhala ndi mawonekedwe abwino komanso othandiza.

Mfundo zazikuluzikulu

PLC Control System

PLC imatengera mawonekedwe amtundu wa Omron / Siemens wowonetsa komanso kuwongolera kwanzeru.

Jekeseni System

Dongosolo lowongolera jekeseni lopangidwa bwino, lokhala ndi magawo osinthika, ndiloyenera kupanga zinthu zambiri zolondola kwambiri.

Hydraulic Control System

Pawiri proportional control mafuta dera, kuthamanga ndi liwiro akhoza kusintha basi.

Clamping System

Mapangidwe apamwamba osinthira makina amatsimikizira makina okhazikika komanso olimba. Makulidwe ndi kutembenuka kumalimbikitsidwa, ndipo manja owongolera apakati apakati amatalikitsidwa ndi 30%, zomwe zimatsimikizira kukhazikika komanso kukhazikika kwa magwiridwe antchito a nkhungu.

Lubrication System

Central automatic lubrication system, kusinthasintha kwanthawi yayitali, kusintha moyo wamakina ndikuchepetsa kukonza.

Ejection System

Makina opangira mphamvu zazikulu, silinda ya ejector iwiri (≥300Ton).

Dulani kapangidwe ka mafuta ozungulira kuti muwonetsetse kuti ma hydraulic system akuyenda bwino.

General luso

Servo Motor Energy Saving System / Mafuta Kuzira System(njira)

1. Kuchita bwino kwambiri komanso kuchita bwino pakupulumutsa mphamvu

Makina oponyera kufa amasintha okha kuthamanga kwamayendedwe kutengera mawonekedwe apakompyuta. Mphamvu zonse zopulumutsa mphamvu zimatha kufika 45% ~ 75%.

2. Phokoso lochepa

Phokoso panthawi yogwira ntchito yocheperako kuposa 65dB, kuti mugwire ntchito mwakachetechete ndikuwongolera malo ogwirira ntchito.

3. Kuyankha mwachangu

Nthawi yonse yoyankha mwachangu ndi yochepera 50ms, ndipo magwiridwe antchito amawonjezeka ndi 5% mpaka 7% pamitundu wamba.

4. Kuwongolera kolondola kwambiri

Kusintha kwa PID kwa kayendedwe ka kayendedwe ka kayendedwe kake ndi kukakamizidwa ndi woyendetsa servo woziziritsidwa ndi mafuta kumapangitsa kuti kubwerezabwereza kwadongosolo lonse lamafuta kumayendetsedwa mkati mwa 0.3% kuti zitsimikizire mtundu wazinthu.

5. Kuwonjezeka kwa moyo wautumiki

Kuthamanga kotsekedwa kawiri kwa kuthamanga kwa kuthamanga kumapangitsa makinawo kuyenda mofulumira komanso mobwerezabwereza, kuchepetsa kwambiri kugunda, kuchotsa kuvala kwa zigawo zosiyanasiyana ndikutalikitsa moyo wautumiki.

Real Time Closed Loop Injection Control System (njira)

Jekeseni yokhala ndi zosintha zenizeni za nthawi yofunikira kuti zitsimikizire kukhazikika kwadongosolo komanso kulondola.

1. Kuthamanga kosalekeza kwa 1st Phase velocity

Konzani gawo loyamba kuti muchepetse kapena kupewa kutsekeka kwa mpweya panthawi yodzazidwa.

2. Kusintha kolondola komanso kofulumira ku gawo lodzaza mwachangu

Kusintha kolondola ndikudzaza mwachangu kuti mukwaniritse njira yoyenera ya jakisoni.

3. Kusintha mwachangu komanso molondola kupita ku gawo lokulitsa

Choyambitsa chachangu komanso cholondola cha gawo la intensification kulola kukakamiza mwachangu kukulitsa nthawi.

4. Kuthamanga kwachangu kumapeto kwa kudzaza kwa zibowo

Braking mu jekeseni wothamanga kwambiri, sikungochepetsa kupangika kwa flash komanso kumawonjezera moyo wautumiki wakufa.

| DC2500 Cold Chamber Die Casting Machine Specification List | |||

| Kanthu | Chigawo | DC2500 | |

| Clamping Unit | Mphamvu yothina | KN | 25000 |

| Clamping stroke | mm | 1500 | |

| Malo pakati pa tayi mipiringidzo (HxV) | mm | 1500 × 1500 | |

| Kukula kwa mbale (HxV) | mm | 2350 × 2350 | |

| Mzere wa bar | mm | 310 | |

| Kunenepa kwa nkhungu | mm | 700-1800 | |

| Mphamvu yotulutsa | KN | 750 | |

| Ejection stroke | mm | 300 | |

| Jekeseni Unit | jekeseni mphamvu | KN | 1800 |

| Jekeseni sitiroko | mm | 1100 | |

| jekeseni malo | mm | -200.-400 | |

| Plunger diameter | mm | 140-180 | |

| Kulemera kwa jekeseni (AL) | Kg | 30-55 | |

| Kulemera kwa jakisoni(MG) | Kg | 21.6-39.6 | |

| Kuthamanga kwapakati (pressurized) | Mpa | 115-70 | |

| Malo oponyamo | CM2 | 2150-3500 | |

| Max. malo oponyera (40MPa) | CM2 | 6250 | |

| Plunger kulowa | mm | 450 | |

| Manja a flange awiri | mm | 280 | |

| Sleeve flange yotuluka kutalika | mm | 30 | |

| Ena | Kupanikizika kwadongosolo | MPa | 16 |

| Mphamvu zamagalimoto | KW | 135 | |

| Kuchuluka kwa tanki yamafuta | L | 3000 | |

| Kulemera kwa makina | Toni | 165 | |

| Kukula kwa makina (L×W×H) | mm | 14000x4600x4500 | |

| DC SERIES COLD CHAMBER DIE CASTING MACHINE STANDARD & ZOYENERA KUSANKHA | |||||||||||||||

| Zosintha | DC180 | DC238 | DC300 | DC350 | DC380 | DC400 | | DC550 | DC700 | DC900 | DC1000 | DC1300 | DC1650 | DC2000 | DC2500 | DC3000 |

| Clamping Unit | |||||||||||||||

| Kuwongolera kofananira kawiri kwa nkhungu kutsegula & kutseka | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Kuwongolera kwakusintha kwapafupi kwa sitiroko yotseguka | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Kuwongolera kwa stroke transducer kwa sitiroko yotseguka | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Fast liwiro nkhungu pafupi | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Kusintha nkhungu pamanja | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Kusintha nkhungu zokha | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Jekeseni Unit | |||||||||||||||

| Jekeseni wa 2 + amalimbitsa kusintha kwa magudumu amanja | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Kuwongolera molingana ndi magetsi | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Proximity switch control stroke | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Imakulitsa malo otsegulira & kuwongolera kuthamanga | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Ejector ndi core kukoka unit | |||||||||||||||

| Promixity switch control ejection stroke | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Single ejection eyeliner | ● | ● | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Ma eyeliner otulutsa kawiri | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-1 imayikidwa pa platen yosunthika | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-2sets pa platen yosuntha | - | - | - | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-1 imayikidwa pa platen yokhazikika | Ο | Ο | Ο | Ο | Ο | Ο | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Core puller-2sets pa platen yokhazikika | - | - | - | - | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Magetsi unit | |||||||||||||||

| Omron PLC / Siemens PLC | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 7 inchi high resolution touch screen | ● | ● | ● | ● | ● | ● | ● | ● | ● | Ο | Ο | Ο | Ο | Ο | Ο |

| 10 inchi high resolution touch screen | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | ● | ● | ● | ● | ● | ● |

| Ena | |||||||||||||||

| Chipangizo chodzidzimutsa | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Plunger lunbrication unit | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο | Ο |

| Ndemanga: 1. ● Standard Ο Option - Osagwiritsidwa Ntchito 2.Tili ndi ufulu wopanga kusintha kulikonse kapena kusintha kwazinthu popanda chidziwitso. |

|||||||||||||||